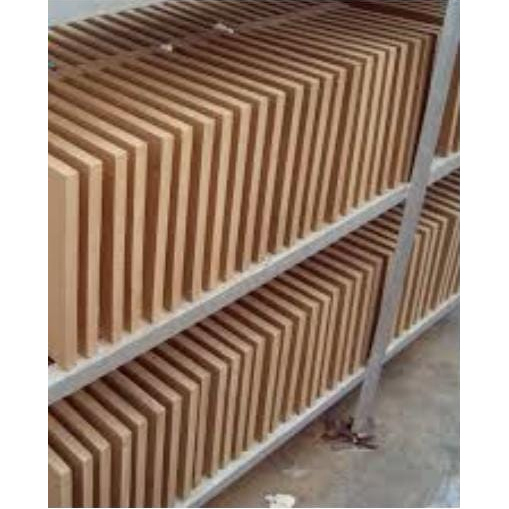

Tundish Board

Price 30 INR/ Set

MOQ : 1 Set

Tundish Board Specification

- Tolerance

- 1 mm

- Back

- Plain

- Grade

- Industrial Grade

- Feature

- High thermal resistance, easy installation, resists slag attack

- Face

- Smooth refractory surface

- Thermal Conductivity

- 0.8 to 1.2 W/mK

- Core Material

- Magnesia or Alumina based refractory

- Usage

- Tundish lining for continuous casting in steel plants

- Size

- As per customer requirement / standard: 910 x 605 mm

- Water Absorption

- <0.5%

- Surface Finish

- Smooth

- Material

- Refractory board

- Thickness

- 20-50 mm

- Load Capacity

- High strength, suitable for molten steel transfer

- Moisture Content

- <1.0%

- Density

- 1.8 Gram per cubic centimeter(g/cm3)

- Shape

- Rectangular panel

- Application Temperature

- Up to 1600C

- Thermal Shock Resistance

- High

- Packaging Type

- Wooden pallet or as required

- Color

- Gray or off-white

- Installation Method

- Manual placement in tundish shell

- Porosity

- 18-20%

- Life Cycle

- Single-use or as per application

- Cold Crushing Strength

- 3 MPa

Tundish Board Trade Information

- Minimum Order Quantity

- 1 Set

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 20 Sets, , Per Day

- Delivery Time

- 7 Days

About Tundish Board

We are an eminent company in this sector, engrossed in designing, manufacturing and supplying superlative quality Tundish Board. This kind of board is the best in quality preformed refractory boards, made up of chosen grade magnesia based material having grain sizes ranging from 0 to 1mm with developed technology in adherence with industry standards. It is absolutely disposable product widely utilized for forming an inner lining for constant casting tundishes ideal for plumbing or metal-founding. Further, Tundish Board can be availed in varied dimensions at feasible prices.

Superior Heat Resistance

This tundish board is engineered to endure temperatures up to 1600C, making it ideal for use during the most demanding steel casting processes. Its magnesia or alumina refractory composition ensures that the lining remains intact and prevents thermal damage during molten steel transfer.

Reliable Strength and Durability

With a cold crushing strength of at least 3 MPa and a dense build (1.8 g/cm3), the board supports high load capacities. Its precise thickness range (20-50 mm) and minimal water absorption (<0.5%) help resist deformation and extend its operational lifespan even under continuous exposure to harsh conditions.

Efficient Installation and Customization

Designed for manual placement within the tundish shell, these panels are available in standard (910 x 605 mm) or customized sizes. The smooth refractory face and plain back facilitate quick, secure installation, reducing downtime during maintenance and changeovers.

FAQ's of Tundish Board:

Q: How is the tundish board installed in steel casting operations?

A: The tundish board is manually placed inside the tundish shell, ensuring complete coverage and a secure fit. Its smooth face and standard or customized sizing allow for quick, efficient installation as part of the continuous casting setup in steel plants.Q: What benefits does the tundish board provide for continuous casting?

A: The board offers high thermal resistance, excellent resistance to slag attack, and strong load capacity for transferring molten steel. These benefits contribute to improved tundish protection, minimized contamination, and optimized casting performance.Q: When should I consider replacing the tundish board?

A: Replacement depends on application requirements-these boards are intended for single-use or as per specific operating conditions. Regular inspection after each casting cycle helps determine if a new lining is necessary to maintain safety and efficiency.Q: Where is this tundish board manufactured and supplied?

A: Manufactured and supplied in India, the product is typically shipped on wooden pallets or packed according to customer specifications, ensuring safe transport and handling to steel plants nationwide.Q: What is the process for customizing board size and specifications?

A: Customers can request board sizes and thicknesses tailored to their tundish dimensions or operational needs. By providing specifications, manufacturers can produce panels with precise tolerance (1 mm) and other required features.Q: What materials are used in the construction of the tundish board?

A: The core material is magnesia or alumina-based refractory, giving the board its high heat resistance and durability. The surface is engineered to be smooth, enhancing installation and resistance to slag infiltration during molten steel transfer.Q: How does the board's high thermal shock resistance benefit steel casting?

A: Its high thermal shock resistance protects the tundish from sudden temperature changes encountered during molten steel casting, reducing the risk of cracks, lining failure, and operational interruptions.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry